Our Contacts

PUGI GROUP srl

- Headquarters -Plant 1: Via Antonio Gramsci 139, Montale 51037 (PT)

- Production Unit -Plant 2: Via Niccolò Tommaseo 144 Pistoia

- Tel. +39 0574 870039

- Fax. +39 0574 870066

- E-mail: info@pugi-group.com

See our featured products

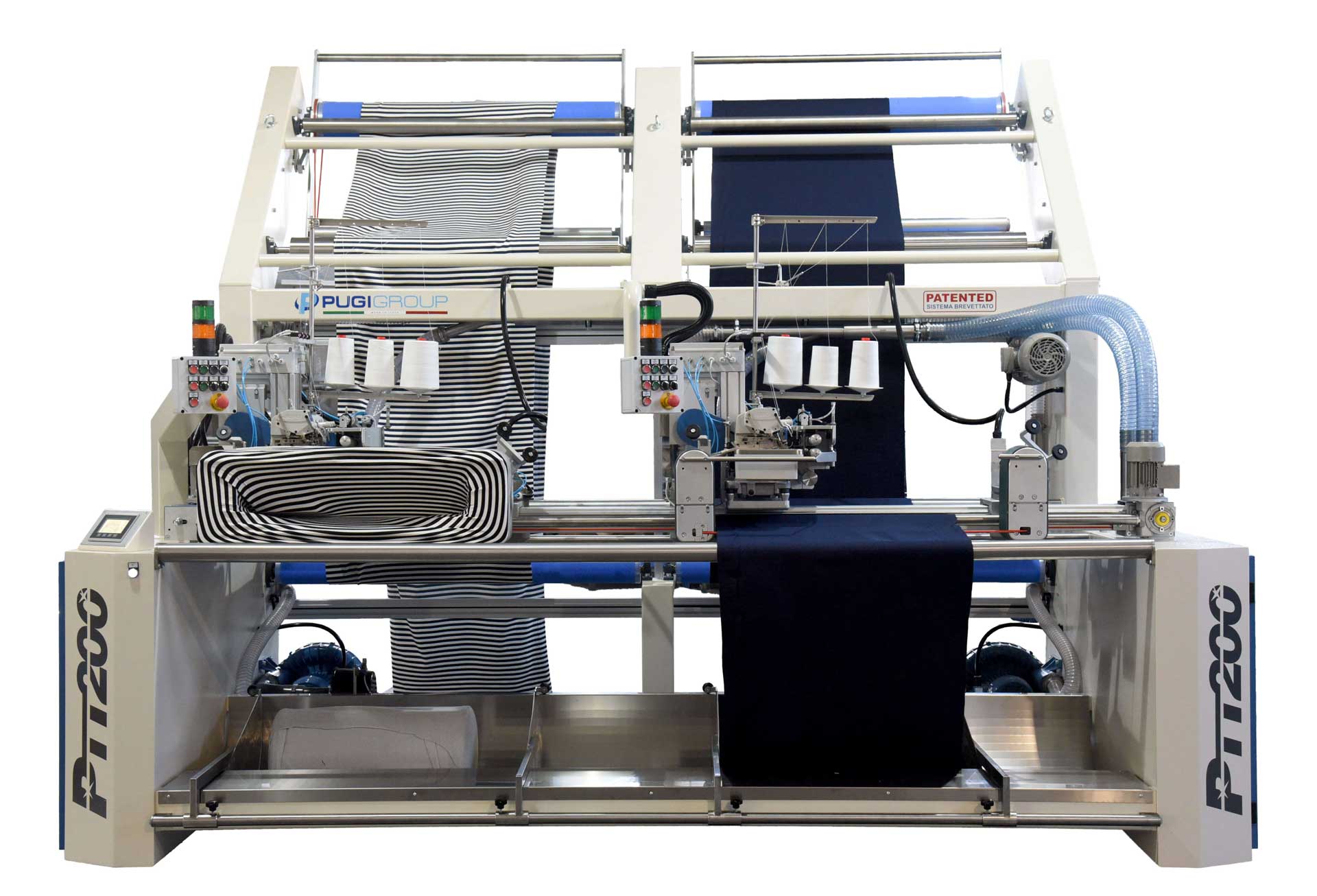

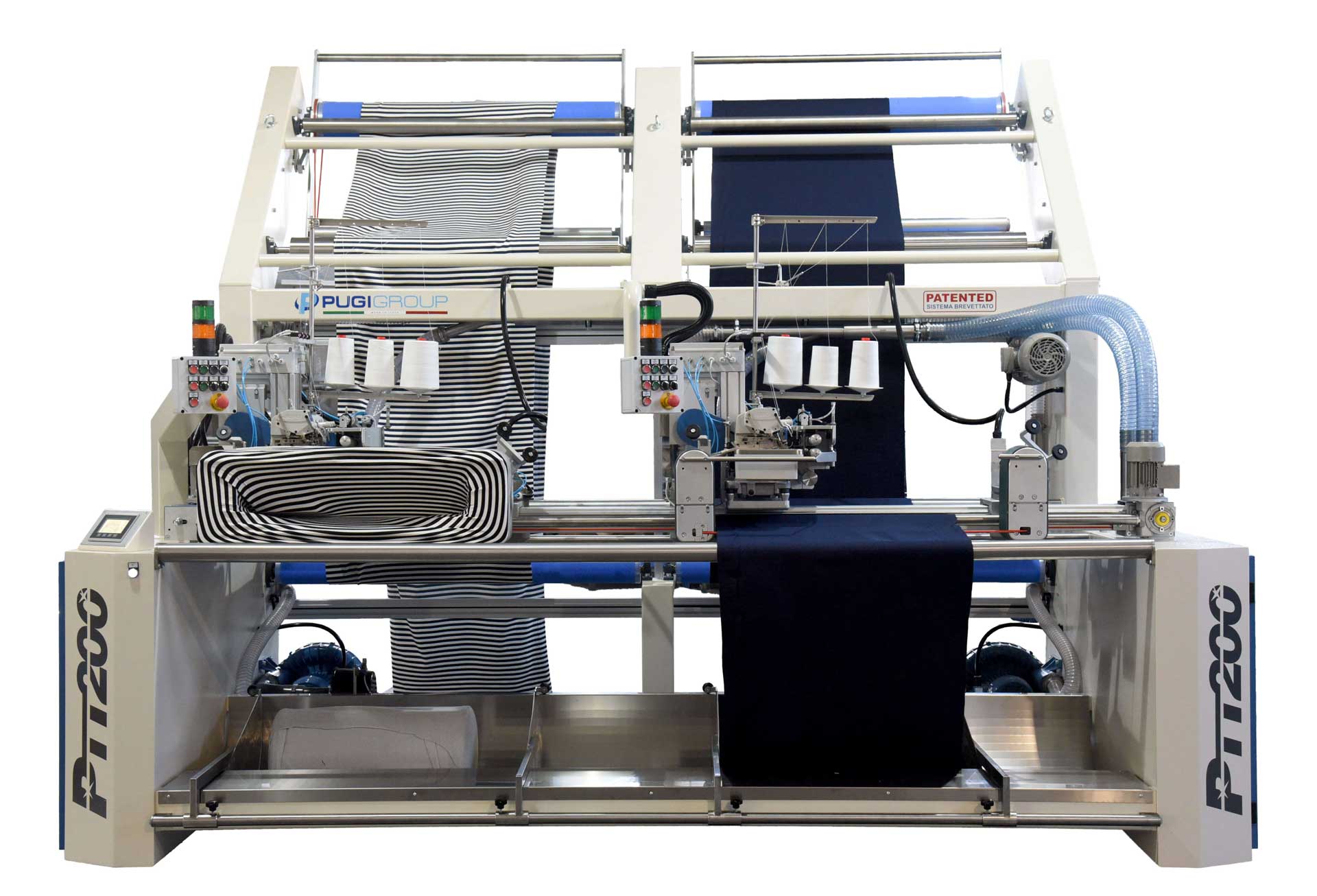

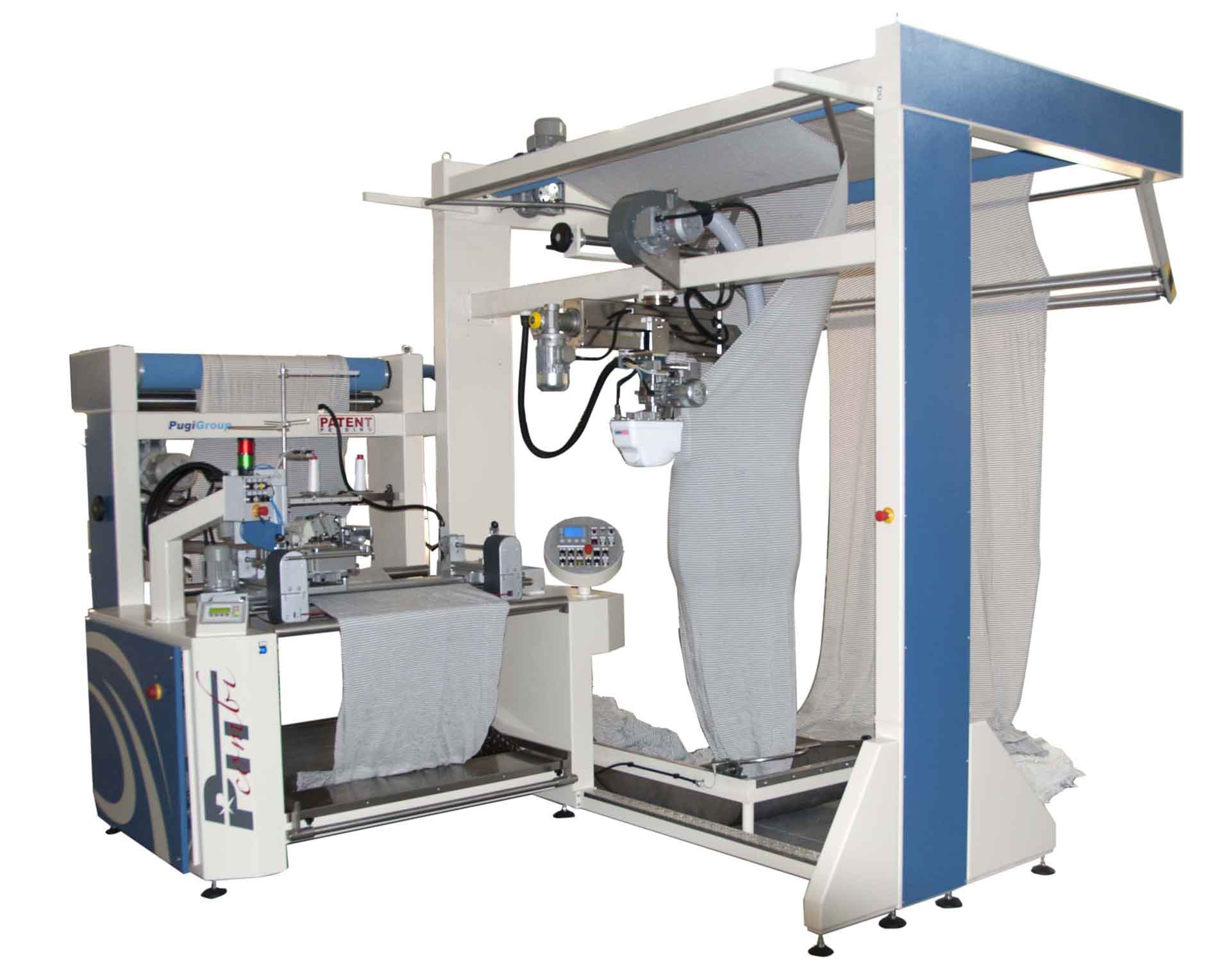

In addition to what described for the PTT-100 model, this double position machine PTT-200 allows one single operator to work on two tubular fabric lines. These two positions, single operator machine expands the out-put capabilities because while one fabric roll end sewn to the other unwinds on the cradle, the operator is able to work on the other sewing station arranging the second fabric line. This machine and the PTT-100 model as well, can use two alternative over lock stitches: one rolled stitch, three threads or one flat stitch, two threads

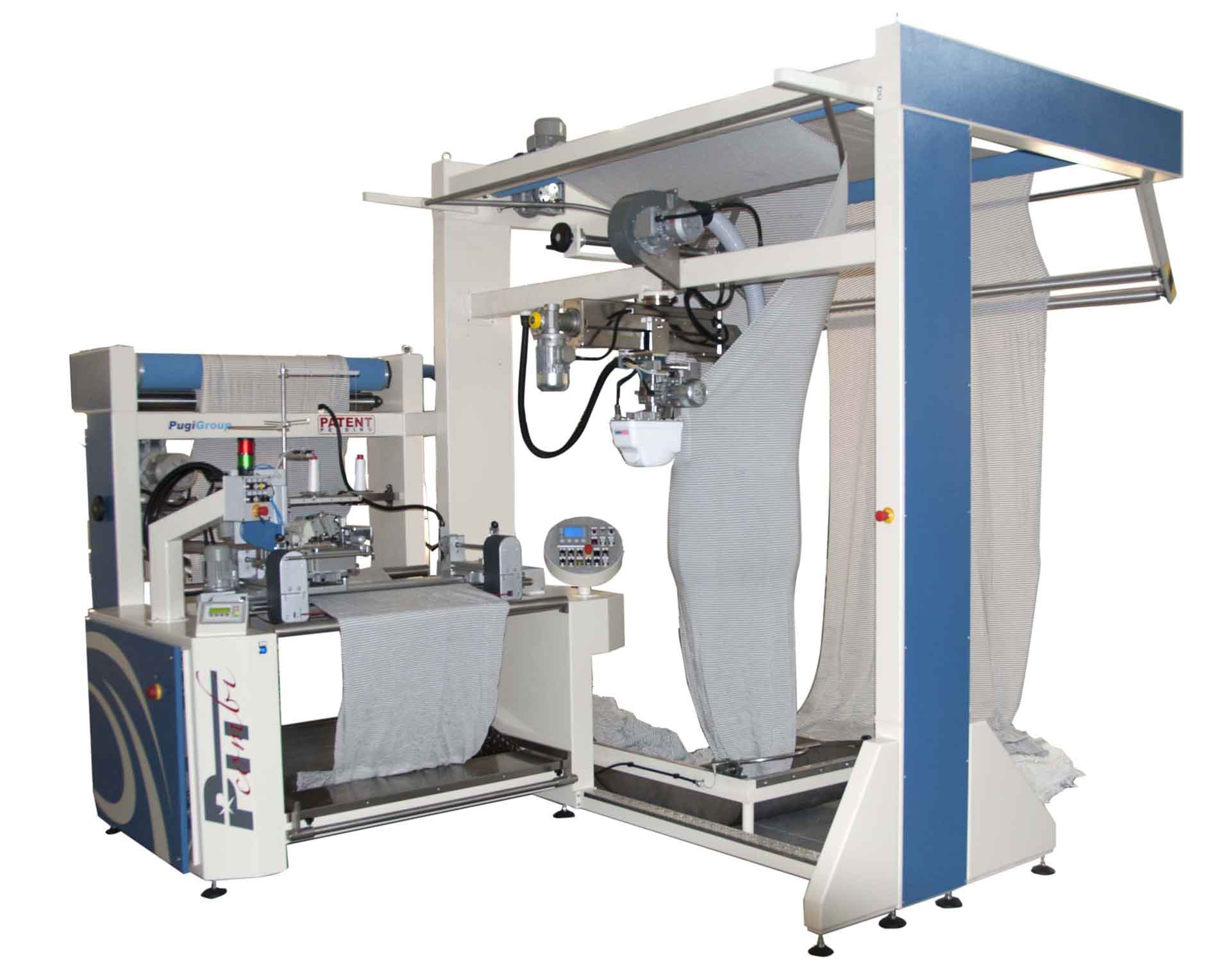

Machine addressed to the dyeing and finishing mills working knitted fabrics in open width. This recent “patented” machine from Pugi Group, other than including all features of the model PTT100, is able to slit the tubular fabric in automatic and synchronized way. This means that while both operations are generally executed in two separate stages, now thanks to this machine, they are carried out simultaneously. The innovative 90° lay out allows one single operator to join end to-end tubular fabrics and to check the slitting operation which anyway occur in a full automatic mode. This is also possible to an optimum system which prepares the fabric to the slitting operation and a high sensitivity photocell which perfectly follows the needle line. Additional advantages are: material space and handling savings.

A new machine designed and created by combining the PTT- 200 machine and the PTT-Combi machine.

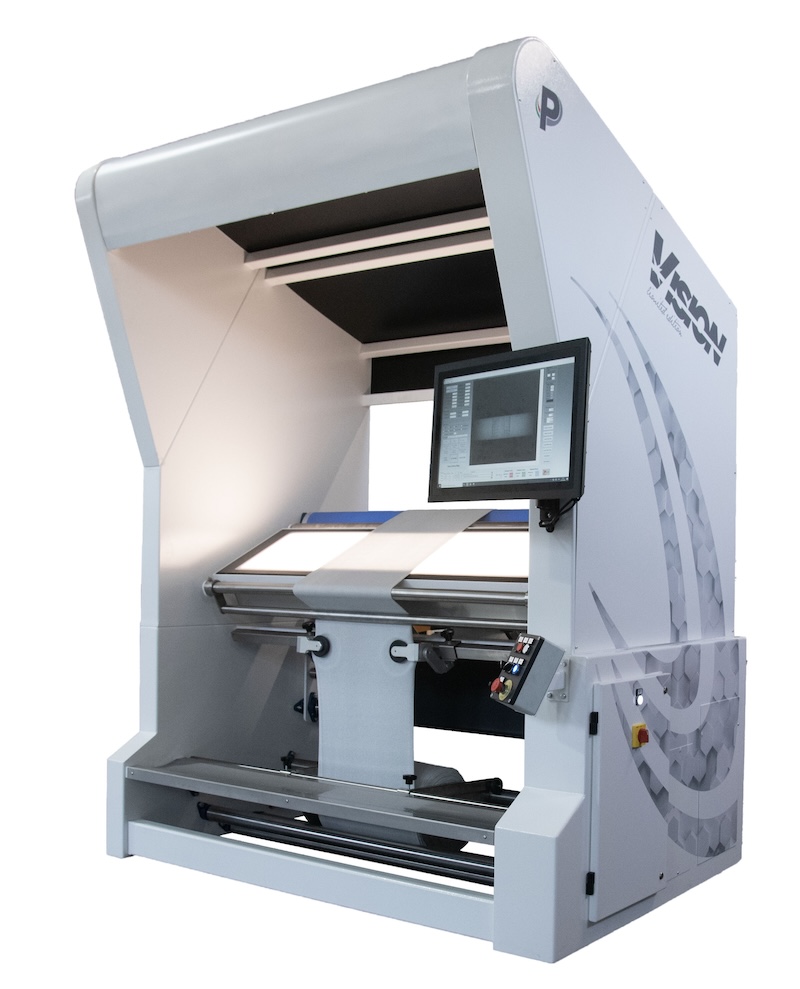

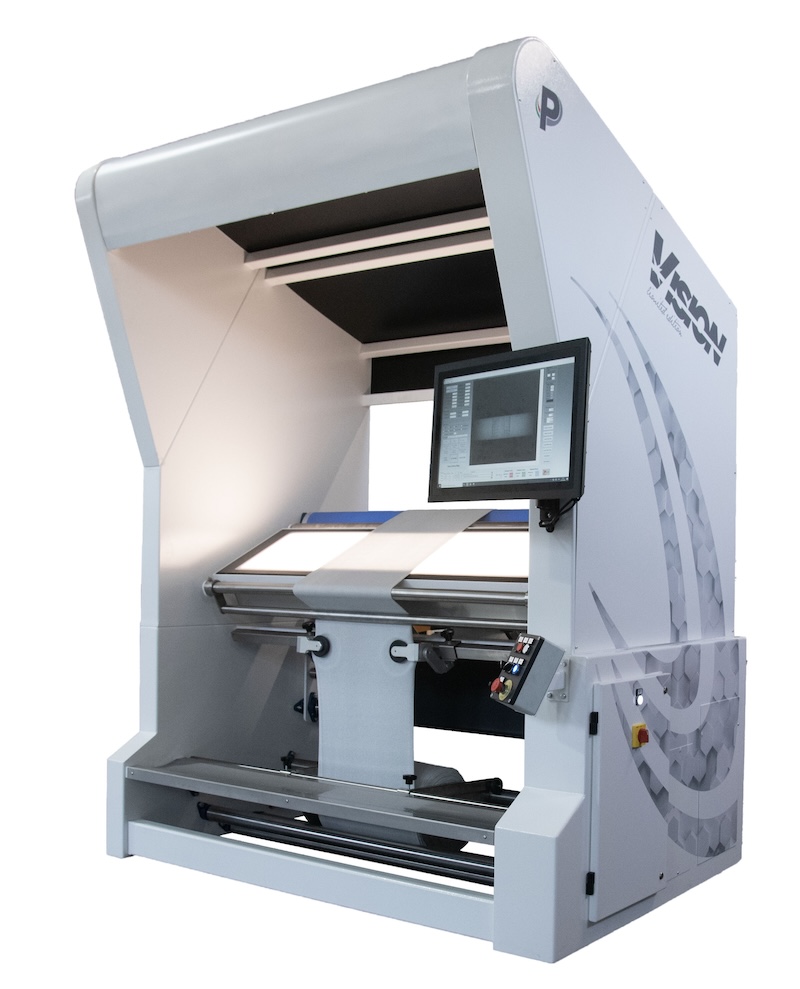

INSPECTION MACHINE WITH CAMERA

Raw fabric defect inspection machine with optical control system

Double lighting system

Fabric infeed in roll

Fabric outfeed folded or in roll

Digital final report

In addition to what described for the PTT-100 model, this double position machine PTT-200 allows one single operator to work on two tubular fabric lines. These two positions, single operator machine expands the out-put capabilities because while one fabric roll end sewn to the other unwinds on the cradle, the operator is able to work on the other sewing station arranging the second fabric line. This machine and the PTT-100 model as well, can use two alternative over lock stitches: one rolled stitch, three threads or one flat stitch, two threads

Machine addressed to the dyeing and finishing mills working knitted fabrics in open width. This recent “patented” machine from Pugi Group, other than including all features of the model PTT100, is able to slit the tubular fabric in automatic and synchronized way. This means that while both operations are generally executed in two separate stages, now thanks to this machine, they are carried out simultaneously. The innovative 90° lay out allows one single operator to join end to-end tubular fabrics and to check the slitting operation which anyway occur in a full automatic mode. This is also possible to an optimum system which prepares the fabric to the slitting operation and a high sensitivity photocell which perfectly follows the needle line. Additional advantages are: material space and handling savings.

A new machine designed and created by combining the PTT- 200 machine and the PTT-Combi machine.

INSPECTION MACHINE WITH CAMERA

Raw fabric defect inspection machine with optical control system

Double lighting system

Fabric infeed in roll

Fabric outfeed folded or in roll

Digital final report

Pugi group has been manufacturing fabric sewing machines and preparation lines for the textile dyeing and finishing industry since 1956.

Without a doubt, PUGI GROUP is today among world leaders in the manufacturing of fabric sewing machines and preparation lines for the textile dyeing and finishing industry, relying on the professional skills of its partners and agents the world over.

See our events