Our Contacts

PUGI GROUP srl

- Headquarters -Plant 1: Via Antonio Gramsci 139, Montale 51037 (PT)

- Production Unit -Plant 2: Via Niccolò Tommaseo 144 Pistoia

- Tel. +39 0574 870039

- Fax. +39 0574 870066

- E-mail: info@pugi-group.com

The machine is suitable for end-to-end joining of both heavy, and very lightweight fabrics, whether wet or dry, with easy to unravel chain stitches. It is particularly suited for knitted fabric.

The SA-3 models can also be used to sew special materials: non-woven fabrics, imitation leather, etc.

MAIN FEATURES OF THE SEWING HEAD

• Sewing head chrome plated, water resistant

• Chain stitch sewing (Models with 1 or 2 needles)

• Stitch length 7 mm.

• Maximum sewing thickness, 12 mm.

• Claw fabric feed

• Oil bath lubrication

• Sewing speed, 1200 stitches/minute

The machine is particularly svitable for end-to-end joining of both heavy and lightweight fabrics, whether wet or dry, with easy to unravel chain stitches. The

SA/12 models can also be used to sew special materials: non-woven fabrics, synthetic furs, imitation leather, etc. The base is mounted on casters for easy manoeuvring even in narrow spaces.

MAIN FEATURES OF THE SEWING HEAD

• Sewing head body: painted cast metal;

• Chain stitch seam (1 or 2 needles version);

• Stitch length: variable from 4 to 8 mm.;

• Max fabric thickness: 12 mm.;

• Fabric traction: spiked wheel;

• Lubrication: manual;

• Sewing speed: 1000 stitches/min.

Overlock Machine suitable for any type of light & medium weight fabrics and particularly suitable for knitted fabrics. Standard electric motor, or battery operated models are available. This machine series fit a “Juki” or similar brand sewing head producing a standard overlock seam with three threads or, on request, a flat seam with two threads.

Buttseaming, flat stitch Machine suitable for any type of fabric with light or medium weight, including knitted fabrics. Standard electric motor, pneumatic motor or battery operated models are offered. On this machines series, the “Merrow” sewing head is used. For wet applications the CNP head is recommended as it has chromium plated inside/outside frame. The rail machine is named MWL able to carry out accurate and straight seams also thanks to a fabric holding bar avoiding any shift of the two fabrics ends during the working cycle.

Buttseaming, flat stitch Machine particularly suitable for woven fabrics with medium & heavy weights. Fabric traction system by spiked disk. Some types of knitted fabrics and light woven can be processed as well. Standard electric motor, pneumatic motor and battery operated models are offered. In order to obtain extremely accurate and straight seams, this type of sewing head is also provided with the linear rail model, named TC14L. The working cycle, completely automatic, occurs in two synchronized stages: (1) brushes pinning & ends cutting, (2) sewing process. This machine also allows getting three different stitches: distanced side-to-side or overlapped.

Full automatic cycle machine not requiring the operator intervention. Operator’s duty is limited to bring the open width fabric at the entrance and taking it already sewn in parallel to the edges, at the machine exit. Thanks to the automatic controls, the two fabric edges are perfectly aligned during the fabric doubling and this condition together with edges depth & stitch length adjustments allow an excellent sewing result. These operations are executed at high speed making the machine highly productive with superior quality results. It is suitable for dry and wet fabrics sewing.

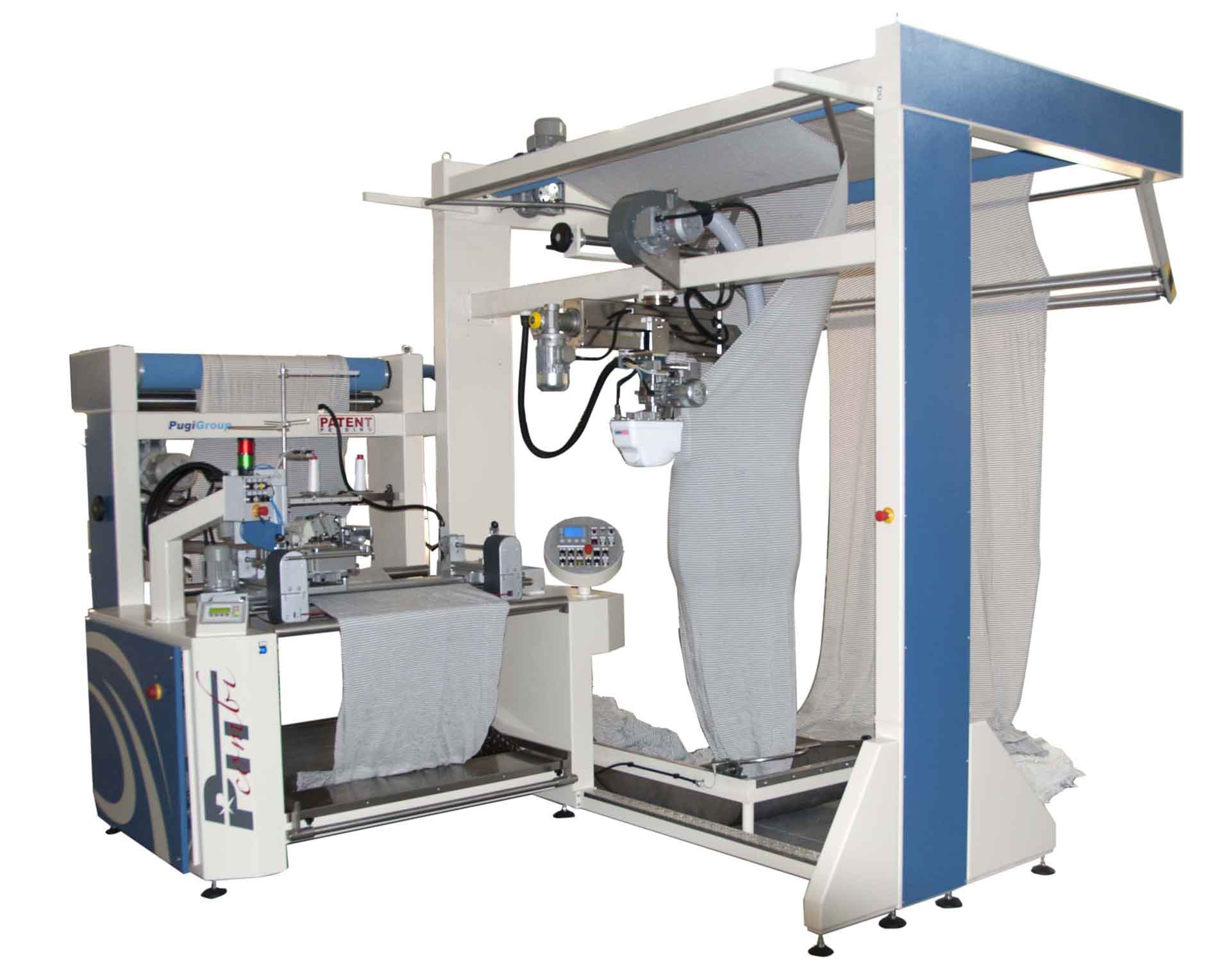

Born from the experience of sewing/bagging machines manufactured by our company e now famous all over the world. Innovation means to stay on line with modern times and to meet customers demand all the time. Mainly designed for knitted fabrics, this new model introduces advanced techniques and a brand new “PANTENTED” system for fabric edges alignment. This allows a perfect fabric doubling and vertical seaming execution; exclusive system allowing high production and quality seam process.

Recent invention machine which totally solves the problems connected to tubular fabrics sewing process. PTT-100 model has one only sewing head but it combines a high production with an excellent result in terms of quality. Among the main features: parallel stitches, minimum fabric waste dramatically reduced and dyeing & finishing processes are improved to parallel and perfect stitches.

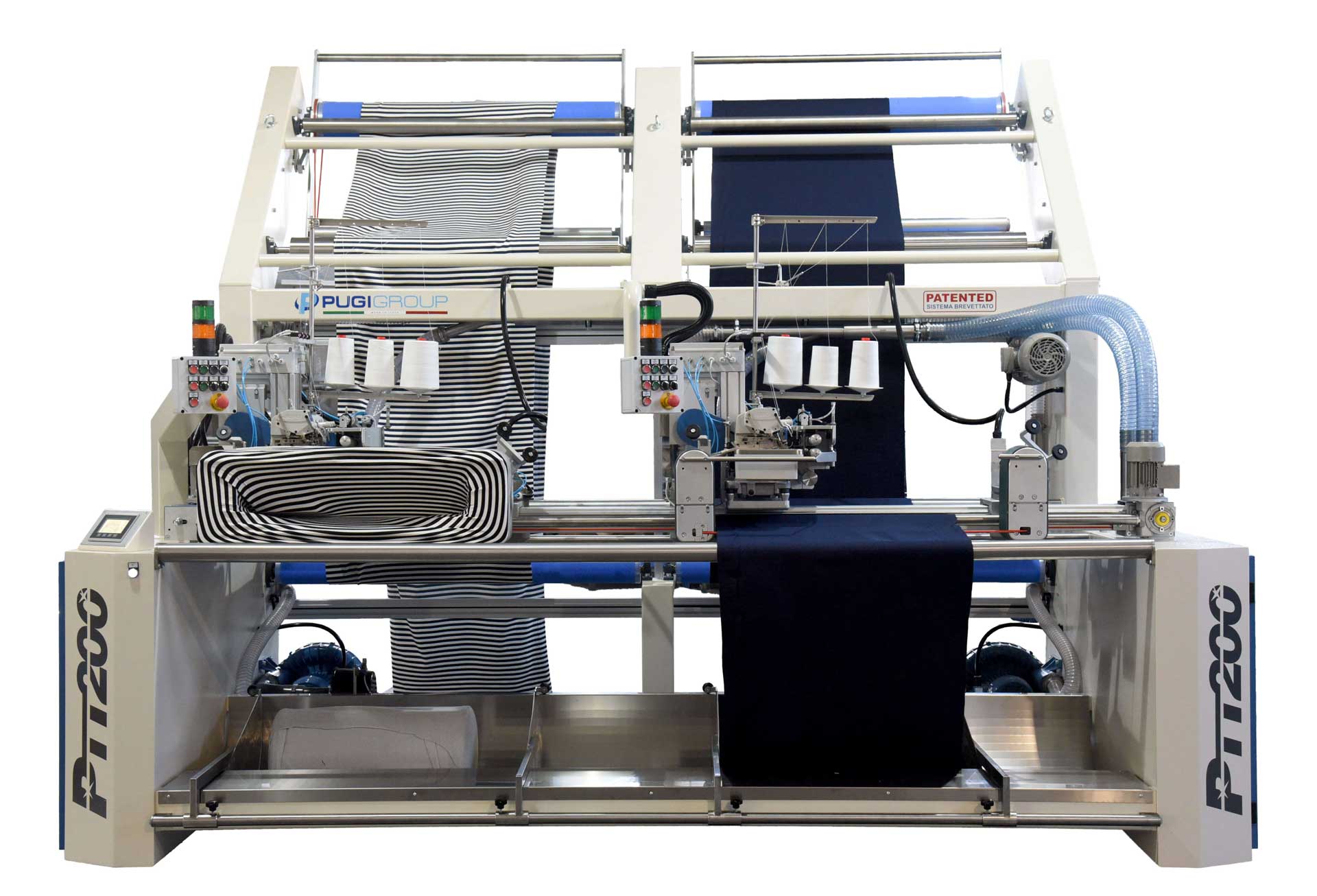

In addition to what described for the PTT-100 model, this double position machine PTT-200 allows one single operator to work on two tubular fabric lines. These two positions, single operator machine expands the out-put capabilities because while one fabric roll end sewn to the other unwinds on the cradle, the operator is able to work on the other sewing station arranging the second fabric line. This machine and the PTT-100 model as well, can use two alternative over lock stitches: one rolled stitch, three threads or one flat stitch, two threads

Machine addressed to the dyeing and finishing mills working knitted fabrics in open width. This recent “patented” machine from Pugi Group, other than including all features of the model PTT100, is able to slit the tubular fabric in automatic and synchronized way. This means that while both operations are generally executed in two separate stages, now thanks to this machine, they are carried out simultaneously. The innovative 90° lay out allows one single operator to join end to-end tubular fabrics and to check the slitting operation which anyway occur in a full automatic mode. This is also possible to an optimum system which prepares the fabric to the slitting operation and a high sensitivity photocell which perfectly follows the needle line. Additional advantages are: material space and handling savings.

A new machine designed and created by combining the PTT- 200 machine and the PTT-Combi machine.

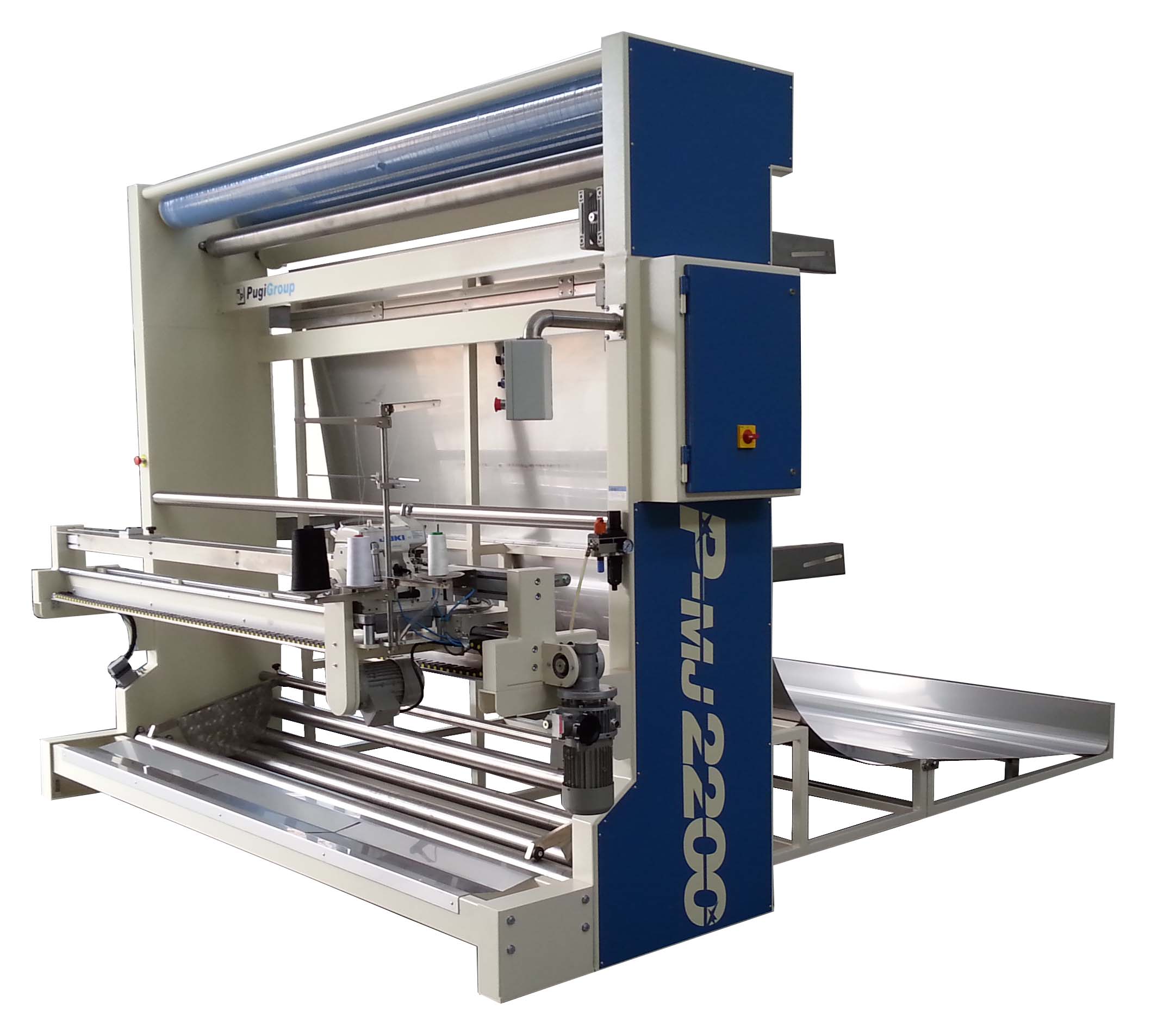

The name P-TC2000 is given to the machine designed to sew and prepare wool, terry, and medium-heavy weight technical fabrics, both woven and non-woven and other types of fabrics. The sewing rail is equipped with a Pugi Group TC 14 L head. A variety of types of fabric preparation machine follow, which may have different configurations.

This machine was created to meet the needs of dyeing houses and finishing mills that must prepare quantities of fabrics sewn together to send them to the subsequent processes. At times underestimated, this stage is very important for the preparation of batches of fabrics with perfectly parallel stitching at high output speeds.

A single base machine structure with an infeed, an exit and various accessories, adapted to the type of fabric being processed.

This machine was created to meet the needs of dyeing houses and finishing mills that must prepare quantities of fabrics sewn together to send them to the subsequent processes. At times underestimated, this stage is very important for the preparation of batches of fabrics with perfectly parallel stitching at high output speeds. A single base machine structure with an infeed, an exit and various accessories, adapted to the type of fabric being processed.

This machine was created to meet the needs of dyeing houses and finishing mills that must prepare quantities of fabrics sewn together to send them to the subsequent processes. At times underestimated, this stage is very important for the preparation of batches of fabrics with perfectly parallel stitching at high output speeds. A single base machine structure with an infeed, an exit and various accessories, adapted to the type of fabric being processed.

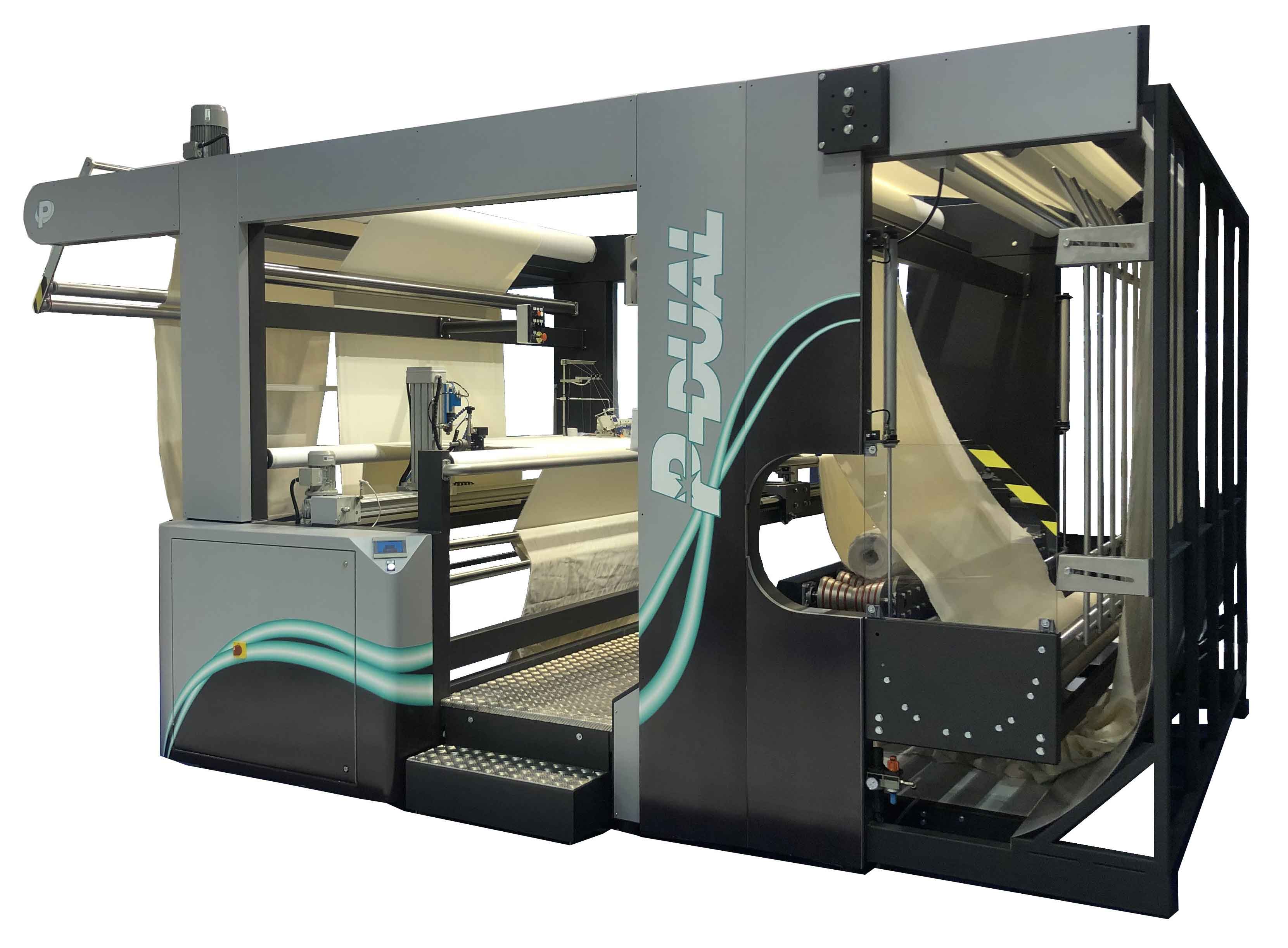

This new machine is the result of a combination of our batching machine for end-to-end sewing of rolls of open width fabric and the machine that prepares selvedge edges on fabrics to be digitally printed. This dual machine gives customers the opportunity to have a multi-functional machine that can execute two production processes simultaneously, or enable only one of the two processes, excluding the other. In this way, machine downtime typical of specific machines that carry out only one process, are completely eliminated.

Fautomatic machine for bilateral overlock stitching of fabric selvedges to prepare for digital printing and in any process that requires selvedges to be well sewn and parallel. machine suited both for woven fabrics and for knits.f

The P-U19 ultrasound sewing machine is designed for continuous overlay stitching of synthetic-thermoplastic textiles. The advantage of the linear structure allows joining fabrics end-to-end with perfectly straight and flat seams, like an overlock seam. The machine is controlled by a microprocessor to ensure reliability and guaranty the quality and repeatability of the seam.

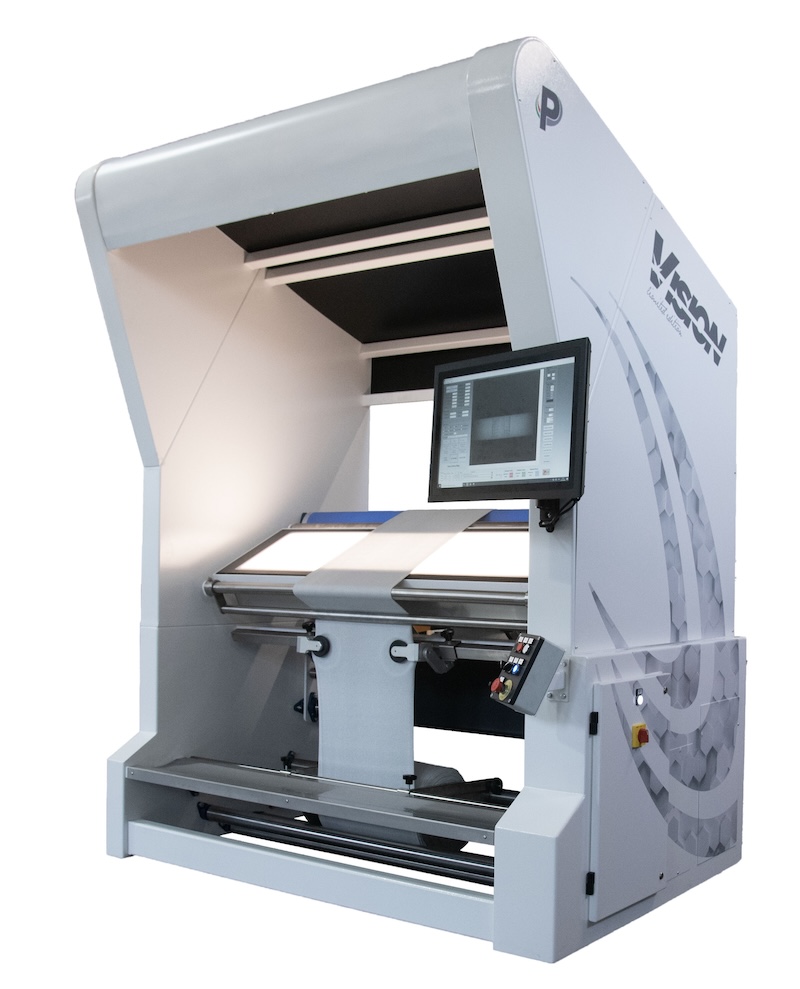

INSPECTION MACHINE WITH CAMERA

Raw fabric defect inspection machine with optical control system

Double lighting system

Fabric infeed in roll

Fabric outfeed folded or in roll

Digital final report

The automatic roll handling systems can be installed on any model of our preparation lines, allowing, in addition to the optimization of production, total safety for the operator in manual handling in compliance with accident prevention regulations

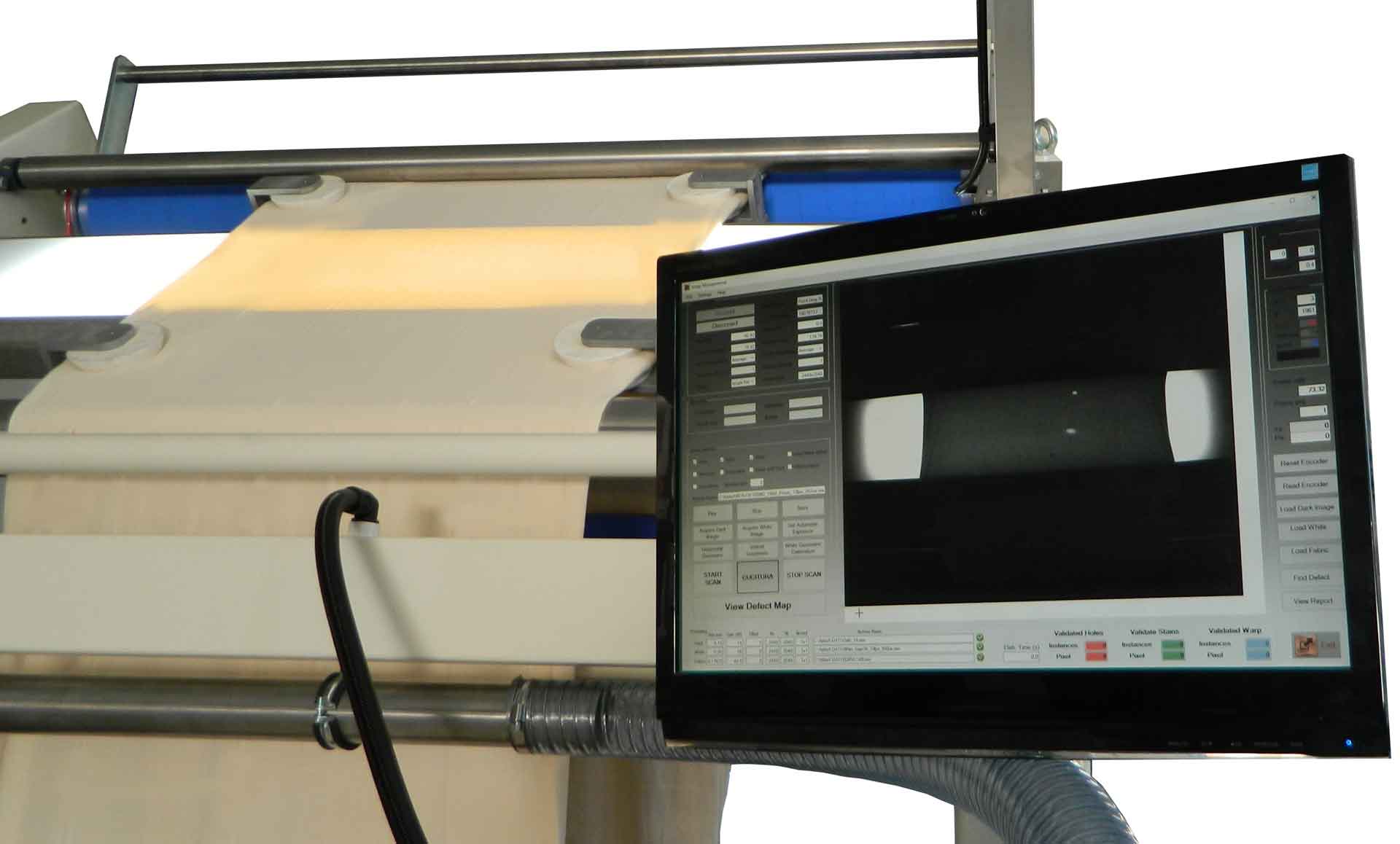

REAL-TIME INSPECTION

VISION is the new advanced optical system aimed at on-line recognition of physical defects of textile fabrics. It is based on latest CMOS Technology and fields an accurate detection, classification and

grading of a wide variety of spatial defects such as holes, stains, and warp/weft faults. Thanks to innovative image processing algorithms based on statistical approach, VISION represents a breakthrough

innovation in inspection technology for tubular as well as open width raw fabrics.

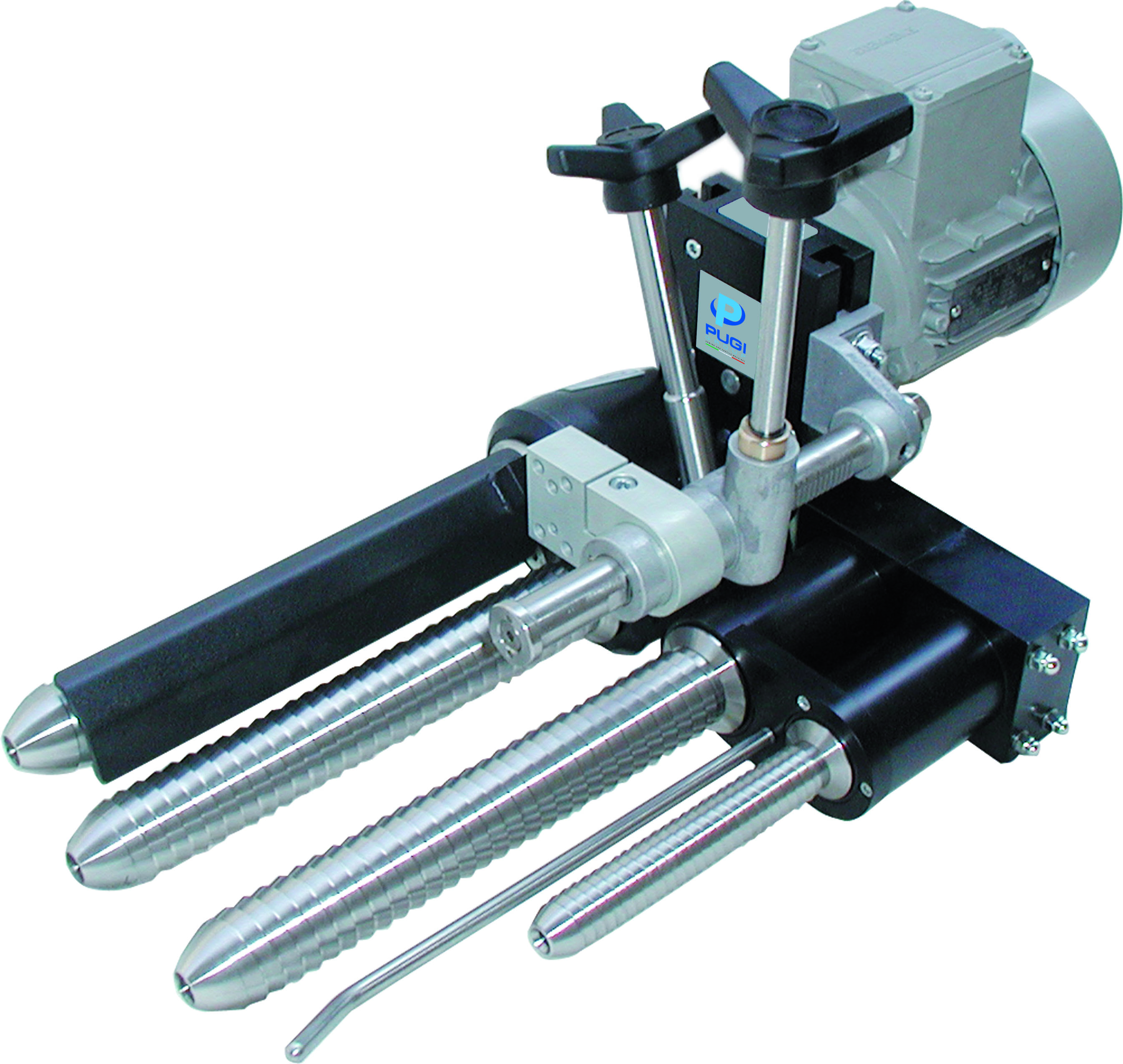

SELVEDGE UNCURLER WITH 2,3 AND 4 SPINDLES In addition to efficiently un curling selvedges of all kinds of fabrics and knits, selvedge uncurler groups also allow connecting additional spindles to the main body in a simple and quick way. On request, models may be provided complete with a positioning device to fasten a sensor for selvedge control. On the SRR model, the drive is indirect and the motor is off-axis with respect to the rotating elements.

SELVEDGE UNCURLER WITH 2,3 AND 4 SPINDLES In addition to efficiently un curling selvedges of all kinds of fabrics and knits, selvedge uncurler groups also allow connecting additional spindles to the main body in a simple and quick way. On request, models may be provided complete with a positioning device to fasten a sensor for selvedge control. The SRD model is equipped with a direct transmission with the motor fitted in line with the rotating elements.

Full stainless steel frame, ideal to work in tandem with rope opener. It is provided with inverter and torque adjustment of the thread winding, variable clutch against thread breakage.